Execution classes (EXC)

EN 1090 – Selection of the correct execution class (EXC)

Since the introduction of EN 1090 in 2012 (transition period until 01.07.2014), manufacturers of construction products must obtain certification from an accredited body. The associated EU regulation is 305/2011.

Informationen über das Thema Schweißen sind finden Sie hier.

Update September 2018:

Although less discussed in this article, it is still interesting: Since September 2018 there is a new edition of EN 1090. Here is an overview of the main changes:

- The fourth part (EN 1090-4) is new. Title: “Technical requirements for load-bearing cold formed steel structural members and load-bearing cold formed components for roof, ceiling, floor and wall applications”.

- New requirements for welds on reinforcing steel and the processing of stainless steels.

- Requirements for cut surfaces now only apply to non-welded edges.

- Annual testing of automated cutting processes now recommended.

- Standard welding processes in EXC3 and EXC4 now possible under certain conditions.

- Crusade tests from now on only from S460.

- New task for the structural engineer: determination of EXC (design class)

- Welding of primed materials only permitted in EXC1. In other design classes, overwelding is now included in the procedure qualification.

- Hole welds must have a minimum radius of 40mm.

- New requirements for fillet welds for component connections.

- Weld seam testing: too small fillet weld thickness is now more closely tolerated.

- New definition of weld seam classes (WIC).

- With new welding instructions: testing of the first five welds by means of non-destructive testing.

The corresponding sheets of EN 1090

- EN 1090-1 requires factory production control and is intended to ensure that non-compliant products do not leave the manufacturing plant. It also regulates how conformity (CE) is to be proven. Once conformity has been proved, the CE mark may be issued.

- EN 1090-2 is a collection of technical rules on how to make steel structures.

- EN 1090-3 is the pedant to EN 1090-2 and contains technical rules for the production of aluminum structures.

- DIN EN 1090 is the German version of DIN, the German Institute for Standardization.

Four execution classes are mentioned within the regulations; in the course of certification of a manufacturing company, an execution class must be selected. Subsequently, a company may only execute orders according to its certified execution class.

Meaning of the execution classes (EXC)

- Execution Class 1 (EXC 1) mainly comprises structures made of steels up to quality S275 that are subjected to static loads. Examples are simple railings (up to 0.5kN/m impact load), stairs or balconies for single-family houses as well as canopies on the non-public ground such as farms or building yards.

- The next higher execution class 2 (EXC 2) includes, in addition to the structures mentioned above, also “non-static loaded” load-bearing structures up to steel quality S700. Typical examples of this design level are simple structures on the public ground such as canopies, stairs, but also supporting structures for commercial buildings (hall construction). Note: All load-bearing structures that do not correspond to EXC 1 EXC 2 or EXC 3 are classified in EXC 2.

- If load-bearing structures are not to be used in a static position (crane runways, road bridges, or flying constructions), they must be classified in EXC 3 or execution class 3.

- Structures with extreme failure consequences are classified in execution class 4. Typically, personal injury and environmental pollution are taken into account here.

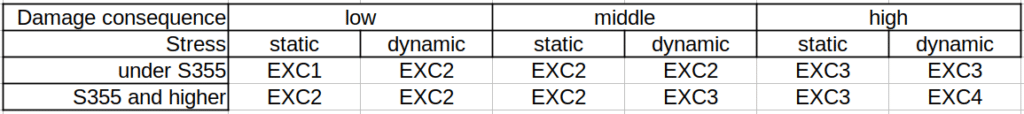

Furthermore, the standard provides a table as a recommendation for classification in EXC1 to EXC4:

Damage Consequence Classes (CC)

The selection of the damage consequence class is recommended as follows:

- Low: Low consequences for human life and small or negligible economic, social and environmental consequences.

- Example: Agricultural buildings without regular passenger traffic.

- Medium: Moderate consequences for human life, adverse economic, social or environmental consequences.

- Example: Residential or office buildings, public buildings with medium consequences of failure.

- High: High consequences for human life or very high economic, environmental or social consequences.

- Example: Grandstands, public buildings with high passenger traffic, concert halls.