Argon 4.6 as an inert shielding gas: Everything you need to know about gas cylinders and argon shielding gas

MSG welding processes such as MIG or TIG use inert gases. A gas is inert if it does not react with its environment. Typical inert gases in welding technology are argon and helium. There is also neon, which is not used in welding. In the following, argon is treated as a welding gas or shielding gas. It is a colourless and odourless gas that has established itself as a shielding gas due to its chemical composition. The chem. Symbol is Ar and is used as a pure gas and as a mixture. When referring to argon with the suffix 4.6, the number is intended to describe the degree of purity. See below for more details.

What is argon 4.6 and why is it used as a shielding gas?

Argon is a noble gas with the symbol Ar in the periodic table of elements. As it is relatively inexpensive and can be easily ionised by electric current, it is often used as a shielding gas. Argon is always used when thermal conductivity is of secondary importance.

Ar is ideal for TIG and MIG welding of high-alloy steels (stainless steel), aluminium materials or non-ferrous metals.

Advantages of argon 4.6 compared to other shielding gases

Argon is always used when the weld pool needs to be protected from oxidation or reduction. The situation is different for welding processes such as MAG welding. Here, gas mixtures are used so that they can react with the weld pool. In the case of high-alloy steels, this would have the disadvantage that alloying elements could burn and thus, for example, the rust protection properties would be lost. There are also gas mixtures with nitrogen, oxygen, CO2 or hydrogen. Up to 5% hydrogen is often added, especially when gas-shielded welding with stainless steel.

- Mild steel: mixed gas or CO²

- Aluminium: Argon or helium

- thinner sheets: Argon

- thicker sheets: helium / argon-helium mixtures

- non-ferrous metals Argon, helium or gas mixtures

Differences between argon, helium and other shielding gases

The shielding gas argon is a rather favourable gas compared to helium. It is easy to ionise and heavier than air. The density is relevant here, as larger flow rates are required at lower densities.

Helium, for example, has a lower density and is lighter than air. In this case, the flow regulator must be turned up a little further. As the thermal conductivity of the gas is higher, the arc also burns hotter. Helium is often used as a shielding gas for thicker metal sheets.

What gas cylinder sizes are available?

Argon gas cylinders are usually available in the following sizes:

- 10 litres (200 bar)

- 20 litres (200 bar)

- 50 litres (200 bar)

- 50 litres (300 bar)

The 10 or 20 litre cylinders are best suited for hobbyists as they are easy to transport. They are also easier to secure in the car.

There are also disposable cylinders. Here is a short video. It doesn’t sound so good, but it is informative on the subject.

How many litres of welding gas does a gas cylinder contain?

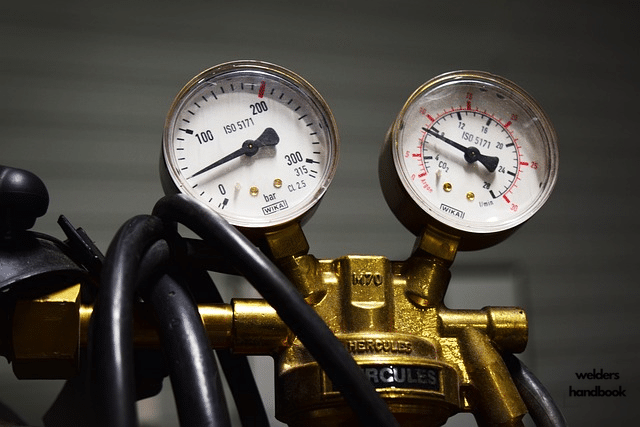

To calculate the content at normal pressure, simply multiply the volume by the pressure. For example, a 10-litre cylinder at standard pressure of approx. 1 bar has a capacity of 2000 litres. A 50-litre bottle at 300 bar, on the other hand, contains 15,000 litres. Attention: Special pressure reducers are used for 300 bar cylinders!

The relevance of the purity grade of argon shielding gas

The addition 4.6 tells us something about the degree of purity. 4.6 stands for a purity of 99.996%. A purity of at least 99.95% should be maintained for TIG welding. The shielding gas argon 4.8 stands for 99.998% purity and is more suitable for special welding applications or the laboratory. The standard in which these regulations are laid down is ISO 14175.

Here is more information on this wonderful shielding gas in FAQ form: